AI + Embedded engineering

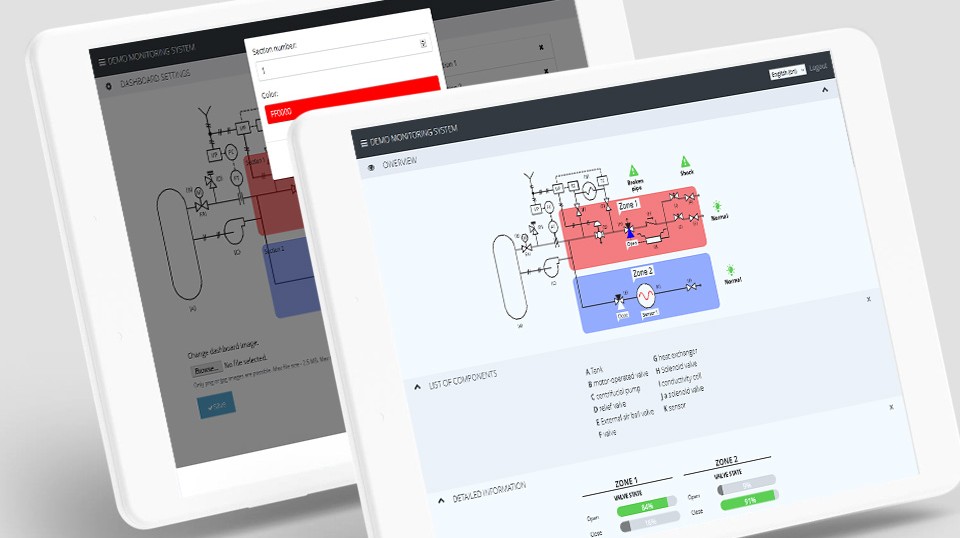

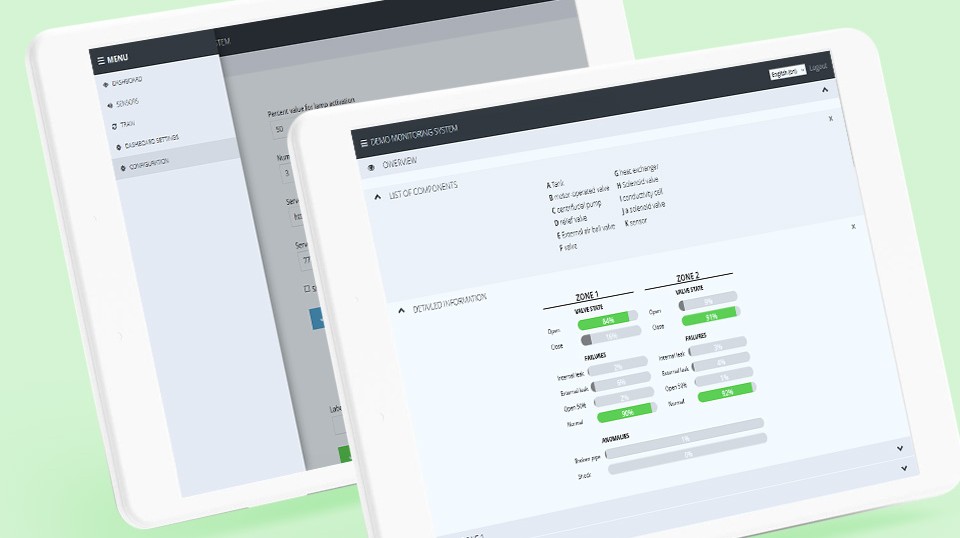

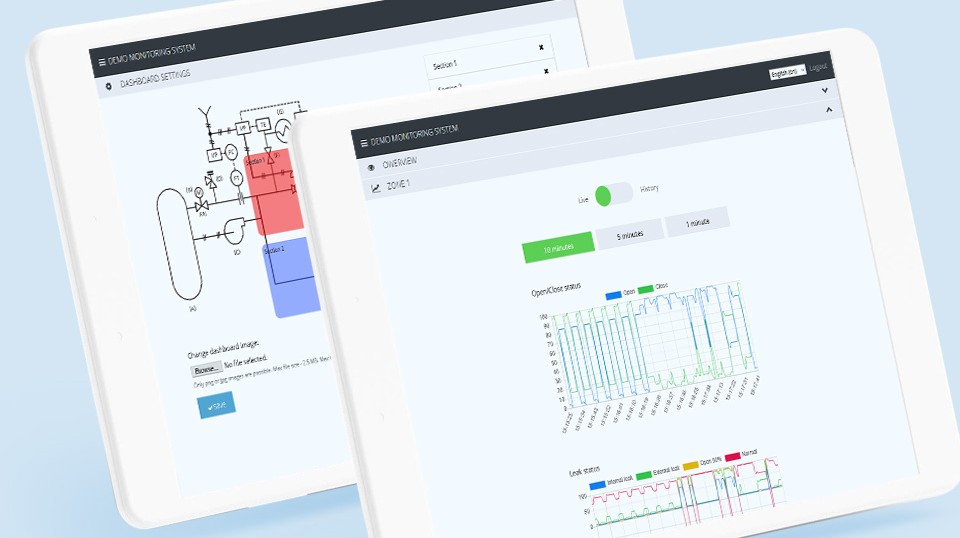

Valve Predictive Maintenance System

Industry

Entertainment

Time

12 month

Team

8 members

Type

Startup